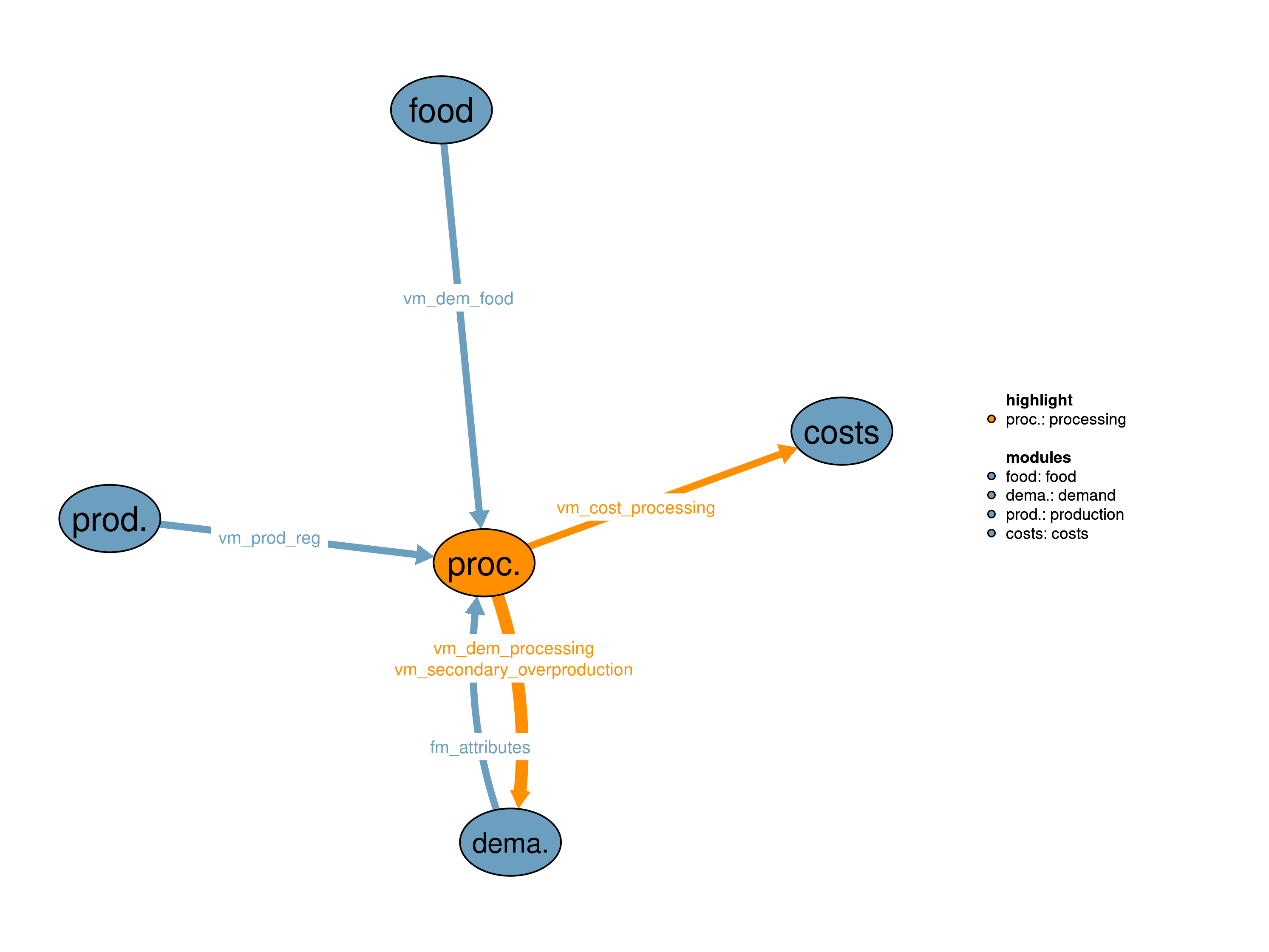

The processing module calculates the quantity of secondary products that are generated through conversion of raw products (especially of primary plant agricultural commodities) in order to meet the demand for those secondary products.

| Description | Unit | A | B | |

|---|---|---|---|---|

| fm_attributes (attributes, kall) |

Conversion factors - where X is ton N P K C DM WM or PJ GE | \(X/tDM\) | x | |

| vm_dem_food (i, kall) |

Food demand | \(10^6 tDM/yr\) | x | |

| vm_prod_reg (i, kall) |

Regional aggregated production | \(10^6 tDM/yr\) | x | x |

| Description | Unit | |

|---|---|---|

| vm_cost_processing (i) |

Processing costs | \(10^6 USD_{05MER}/yr\) |

| vm_dem_processing (i, kall) |

Demand for processing use | \(10^6 tDM/yr\) |

| vm_secondary_overproduction (i, kall, kpr) |

Overproduction of secondary couple products | \(10^6 tDM/yr\) |

This realization describes the conversion process of primary to secondary agricultural products. Secondary products are produced through some sort of mechanical or chemical processing of primary crops. By secondary products we only refer to those for which information is available in Commodity Balance sheet of FAOSTAT (2016). Among others, press cakes from oil production, molasses and bagasses from sugar refinement and brans from cereal milling are important ones. The use of these secondary products is given in the 16_demand module.

The series of equations below show the aggregation of secondary products from from non-cereals (through alcohol fermentation, single cell protein breeding, oil extracting, sugar refining or ethanol distilling processes), cereals (through milling process), and cotton (through ginning process). The need to have such multiple equations (i.e., separate equations for each process) is meant to replicate the structure of Commodity Balance Sheets in FAOSTAT (2016).

In the first equation, the demand for processing use is calculated by aggregating the demand for secondary (processed) products use by process type (other than milling and ginning in this equation case). The equation also calculates secondary products from non-cereals crops such as bio-energy crops and oil crops.

\[\begin{multline*} vm\_dem\_processing(i2,kpr) = \sum_{no\_milling\_ginning20}v20\_dem\_processing(i2,no\_milling\_ginning20,kpr) \end{multline*}\]

In the second equation, the demand for processed products by process type of milling of cereal crops is calculated. The equation applies only to secondary products from cereal crops which, among others, include maize, tropical and temperate cereals. Nevertheless, as in Commodity Balance Sheets of FAOSTAT (2016), cereal milling here is not counted as processing but derived from food use of cereals.

\[\begin{multline*} vm\_dem\_food(i2,kcereals20) = v20\_dem\_processing(i2,"milling",kcereals20) \end{multline*}\]

In the third equation, the demand for processing by process type v20_dem_processing of ginning of cotton is calculated. Likewise, the Commodity Balance Sheets in FAOSTAT (2016) do not account for processing of “seed cotton” into “cotton seed” and “cotton lint”. As MAgPIE only includes the product “cotton seed” and not “seed cotton”, the “cotton lint” is bound to the production of “cotton seed”.

\[\begin{multline*} vm\_prod\_reg(i2,"cottn\_pro") = v20\_dem\_processing(i2,"ginning","cottn\_pro") \end{multline*}\]

The fourth equation below describes the transformation of primary products into secondary products. The processing conversion factors (f20_processing_conversion_factors_cf) indicate how much secondary products can be derived from one unit of a specific primary product. To avoid perfect substitutability between different primary commodities being transformed into the same secondary product (e.g. oil from sunflower or oil palm), we use share factor coefficients, f20_processing_shares, which indicate how much of the secondary products comes from which primary products. The parameter f20_processing_balanceflow accounts for differences in conversion efficiency among various countries whereas the conversion factors remain global. The v20_secondary_substitutes are used to avoid overproduction of couple products: for each couple product, there is one secondary product (usually the cheaper one) which can be substituted by other commodities (see also equations below). The secondary product overproduction vm_secondary_overproduction is used to move overproduction of secondary products into the waste category such that the demand balance is maintained (see also 16_demand).

\[\begin{multline*} \sum_{processing20}\left( v20\_dem\_processing(i2,processing20,kpr) \cdot \sum\left(ct,f20\_processing\_conversion\_factors(ct,processing20,ksd,kpr)\right)\right) = \left(vm\_prod\_reg(i2,ksd) - \sum_{ct}f20\_processing\_balanceflow(ct,i2,ksd)\right) \cdot \sum_{ct}f20\_processing\_shares(ct,i2,ksd,kpr) - v20\_secondary\_substitutes(i2,ksd,kpr) + vm\_secondary\_overproduction(i2,ksd,kpr) \end{multline*}\]

The fifth equation below replaces the couple products bran oil and germ oil by other oils.

\[\begin{multline*} v20\_dem\_processing(i2,"substitutes","oils") \geq \sum_{kcereals20} v20\_secondary\_substitutes(i2,"oils",kcereals20) \end{multline*}\]

The sixth equation below replaces brans by cereals of same protein value.

\[\begin{multline*} \sum_{kcereals20}\left( v20\_dem\_processing(i2,"substitutes",kcereals20) \cdot fm\_attributes("nr",kcereals20)\right) \geq \sum_{kcereals20}\left( v20\_secondary\_substitutes(i2,"brans",kcereals20) \cdot fm\_attributes("nr","brans")\right) \end{multline*}\]

The seventh equation in this realization calculates the costs of processing (or converting) primary products to secondary products. As shown in the equation, the costs of processing (converting from primary to secondary products) depend on the type of the primary product (e.g. maize, sugar cane, cotton), the type of the process (e.g. milling, refining, ginning), and the type of secondary product (e.g. brans, sugar, fiber) product. The unit costs of processing, f20_processing_unitcosts, are specific for the different conversion routes and are collected, interpolated, and extrapolated from the related literature (e.g. Adanacioglu and Olgun (2011), Pikaar et al. (2018), Valco et al. (2016)) complemented with best educated guess by the module authors.

\[\begin{multline*} vm\_cost\_processing(i2) = \sum_{ksd,processing20,kpr}\left( v20\_dem\_processing(i2,processing20,kpr) \cdot \sum_{ct}f20\_processing\_conversion\_factors(ct,processing20,ksd,kpr) \cdot f20\_processing\_unitcosts(ksd,kpr)\right) \end{multline*}\]

Limitations Costs of processing depend on unit costs of processing collected, interpolated, extrapolated, and adjusted from a scant literature.

This realization uses an arbitrary unit cost of processing which is too high for many of the processing types and secondary products. So doing is meant to discourage overproduction of secondary products. Despite these limitations, however, the implementation is very simple as it uses the same unit costs of processing for all second products (e.g. alcohol, ethanol, molasses, brans) and processing types (e.g. fermentation, ginning, milling, breeding).

The equation of this realization is straight forward. Costs of processing are calculated by the product of the quantity of secondary products and the unit processing costs and unit processing costs (which arbitrarily is set to be 5000 USD for all processing types and secondary products).

\[\begin{multline*} vm\_cost\_processing(i2) = \sum_{ksd}\left( vm\_prod\_reg(i2,ksd) \cdot 5000\right) \end{multline*}\]

Limitations There is no empirical ground to use the same unit costs of processing for all processing types and secondary products, and to impose constraint on over production of secondary products.

| Description | Unit | A | B | |

|---|---|---|---|---|

| f20_processing_balanceflow (t_all, i, ksd) |

Processing balance flow | \(10^6 tDM\) | x | |

| f20_processing_conversion_factors (t_all, processing20, ksd, kpr) |

Conversion factors of primary products into secondary products | \(1\) | x | |

| f20_processing_shares (t_all, i, ksd, kpr) |

Shares of secondary products coming from a primary product | \(1\) | x | |

| f20_processing_unitcosts (ksd, kpr) |

Costs of transforming x units kpr into 1 unit ksd | \(USD_{05MER}/tDM\) | x | |

| q20_processing (i, kpr, ksd) |

Processing equation | \(10^6 tDM/yr\) | x | |

| q20_processing_aggregation_cereals (i, kcereals20) |

Connecting processing activity to food use for milling | \(10^6 tDM/yr\) | x | |

| q20_processing_aggregation_cotton (i) |

Connecting processing activity to production for cotton ginning | \(10^6 tDM/yr\) | x | |

| q20_processing_aggregation_nocereals (i, kpr) |

Connecting processing activity to processing flows | \(10^6 tDM/yr\) | x | |

| q20_processing_costs (i) |

Processing costs | \(10^6 USD_{05MER}/yr\) | x | x |

| q20_processing_substitution_brans (i) |

Substitution of brans by cereals | \(10^6 tDM/yr\) | x | |

| q20_processing_substitution_oils (i) |

Substitution of branoils by other oils | \(10^6 tDM/yr\) | x | |

| v20_dem_processing (i, processing_subst20, kpr) |

Demand for processing use by process | \(10^6 tDM/yr\) | x | |

| v20_secondary_substitutes (i, ksd, kpr) |

Substitutes for inferior secondary products | \(10^6 tDM/yr\) | x |

| description | |

|---|---|

| attributes | Product attributes characterizing a product (such as weight or energy content) |

| ct(t) | Current time period |

| i | World regions |

| i2(i) | World regions (dynamic set) |

| kall | All products in the sectoral version |

| kcereals20(kpr) | Cereals used for processing |

| knpr(kall) | Products that cannot be processed |

| kpr(kall) | Products that can be processed |

| ksd(kall) | Secondary products |

| no_milling_ginning20(processing_subst20) | Processing activities without milling and ginning |

| processing_subst20 | Processing activities |

| processing20(processing_subst20) | Processing activities except substitution |

| t_all | 5-year time periods |

| t(t_all) | Simulated time periods |

| type | GAMS variable attribute used for the output |

Benjamin Leon Bodirsky, Amsalu Woldie Yalew

11_costs, 15_food, 16_demand, 17_production

Adanacioglu, Hakan, and F. A. Olgun. 2011. “Profitability and Efficiency in the Cotton Ginning Industry: A Case Study from the Aegean Region of Turkey.” custoseagronegocioonline.

FAOSTAT. 2016. “FAOSTAT Database.” Rome: The Food; Agriculture Organization of the United Nations (FAO). http://www.fao.org/faostat/en/.

Pikaar, I., S. Matassa, B. L. Bodirsky, I. Weindl, F. Humpenöder, K. Rabaey, N. Boon, et al. 2018. “Decoupling Livestock from Land Use Through Industrial Feed Production Pathways.” Environmental Science and Technology 52 (13): 7351–9. https://doi.org/10.1021/acs.est.8b00216.

Valco, T. D., H. Ashley, D. S. Findley, J. K. Green, R. A. Isom, and T. L. Price. 2016. “The Cost of Ginning Cotton - 2016 Survey Results.” National Cotton Ginners Association.